Wind turbine blade recycling: the high stakes, real solutions & road to circularity

Wind energy has become one of the defining pillars of the global energy transition. Turbines dot landscapes, both onshore and offshore, delivering clean electricity. Yet, as the first generation of turbines ages, a pressing issue looms: what to do with the blades when their operational life ends? Unlike towers or nacelles made predominantly of metals, blades are composite structures built to resist stress, fatigue, and environmental damage. That very sturdiness that helps them generate clean energy also makes them extremely difficult to recycle.

This article explores: the scale of wind turbine blade waste recycling now and forecast to 2050; exactly what materials make up blades and why those materials complicate things; detailed recycling and repurposing technologies and their readiness; policy, economic, and regulatory levers and what must change to make 100% or near‑100% circularity realistic rather than aspirational.

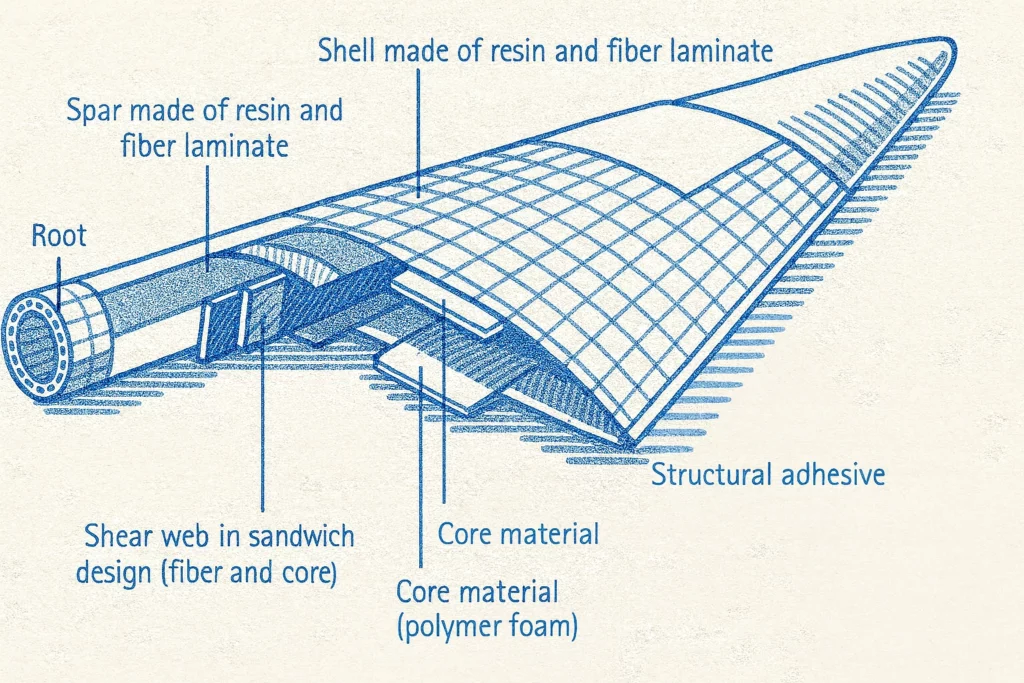

Material composition & why it matters

Image: Cross-section of wind turbine blade

Understanding what blades are made of is essential for designing recycling pathways.

| Component | Typical material(s) | Purpose / desired properties | Implication for recycling |

|---|---|---|---|

| Blade shell / skin (outer laminate) | Glass‑fiber reinforced polymer (GFRP); sometimes carbon‑fiber reinforced polymer (CFRP) in high‑performance or large blades | High strength‑to‑weight ratio; stiffness; resistance to fatigue, weather, UV | Fibers are difficult to free from resin; thermoset resins (epoxy, polyester) don’t melt or re‑soften; fiber damage in mechanical processes reduces value. |

| Core / sandwich structure | Cored with foam (PVC, PET, polyurethane foams), balsa wood, sometimes honeycomb cores, adhesive layers | Light weight; maintain shape; manage loads; offer stiffness while keeping mass down | Mixed materials: resin + foam + adhesives → difficult separation, contamination, added cost of delamination; adhesives often incompatible with reuse. |

| Resins, adhesives & coatings | Epoxy resins dominate; polyester resins; polyurethane adhesives; gel‑coats; protective paints and coatings | Bonding, protecting from moisture and UV, aerodynamic smoothness | Thermoset resins are chemically cross‑linked: cannot remelt; coatings may contain toxic or difficult substances; adhesives add another barrier to separation. |

| Other embedded materials | Lightning protection (metal conductors), sensors, composite reinforcements, metal inserts, sometimes carbon fiber reinforcements | Safety; monitoring; structural integrity; weight savings or specialized strength | Metals are recyclable, but need removal; sensors/adapters complicate automated recycling; carbon fibers often more valuable but harder to recover without damage. |

Because of these composite mixes—thermosets, resins, fibers, core materials—blades represent a complex recycling engineering problem, not just an economic or logistical one.

Struggling with retired turbine blades? We identify the most cost-effective, regulation-compliant processing and recycling plants for your specific waste volume, location, and blade type.

Contact us:

Scale of the problem: waste volumes & projections

The magnitude of blade waste is already large, and projected growth is dramatic.

- Globally, by 2050, cumulative blade waste is forecasted at about 43 million tonnes (25% of said waste is generated by Europe)

- According to recent data, the annual rate of waste from wind turbines will reach roughly 2.9 million tonnes per year globally in just a few years. In Europe alone various sources project 400,000 tons per year of blade waste by 2030, rising to ~800,000 tons annually by 2050.

- According to windeurope.org Germany alone will generate about 23,300 tonnes of blade waste (in some reporting period), Spain ~16,000 tonnes, Italy ~2,300 tonnes.

Beyond sheer tonnage, the waste stream is growing because:

- Many early‑turbine fleets (1990‑2000s) are now reaching or exceeding design lifespans (20‑30 years).

- Repowering (replacing old turbines with fewer, more powerful ones) means many old blades come down even if tower foundations remain.

Understanding these numbers helps show that disposal or inefficient recycling is unsustainable—not just environmentally, but economically and socially.

What happens now: disposal & existing recycling practices

Before jumping to new technologies, it’s essential to map what the current common pathways are, and how good or bad each is.

| Pathway | What happens | Advantages | Disadvantages / Environmental costs |

|---|---|---|---|

| Landfill | Blades (cut up or whole) end up in landfill, often after basic shredding | Low immediate cost; existing infrastructure; familiar legal framework | Wastes composite materials; takes up space; leaching or micro‑fiber generation; environmental liability; policy risk as bans increase. |

| Incineration / Co‑processing in cement kilns | Burning or partial burning in industrial plants to recover energy or for material substitution (e.g. fuel in cement kilns) | Energy recovery; uses established industrial channels; sometimes cheaper than full recycling | Emissions, often low net benefit; fiber lost; regulatory and permitting challenges; often still seen as “last resort”. |

| Mechanical recycling | Grinding, shredding, mechanically separating fiber fragments; reuse as filler, aggregate, low‑value composites | Technology relatively mature; lower cost; uses existing machinery; can reduce waste volume; provides some material benefit | Fibers are shortened and lose strength; resin remains, so quality lower; often only feasible for low‑value uses; still expensive labor and transport. |

| Chemical recycling (solvolysis, pyrolysis, etc.) | Use solvents, heat, or supercritical fluids to dissolve or break resin bonds, recover fibers and potentially resins | Can potentially preserve fiber strength; higher value reuse; more circular outcomes; possibly lower environmental footprint if done right. | Currently pilot scale; high energy or chemical demands; cost heavy; safety, regulation, solvent recycling/disposal issues; scale‑up challenges. |

| Repurposing / Upcycling | Transforming whole blades or parts into other structures (e.g. playgrounds, noise barriers, sculptures, bridges) | Extends lifetime; often lower processing requirement; community / educational value; visible proof of circular ideas. | Transport of large elements is expensive; design, engineering and safety requirements often restrictive; limited number of reuse opportunities; durability in repurposed uses sometimes questionable. |

Innovations & next‑generation solutions

To break out of “waste problem” mode, recent research and industrial efforts have been pushing new materials, new recyclability, and new value chains.

Enhanced chemical wind turbine blade recycling routes

- Solvolysis: Where solvents (sometimes supercritical fluids, sometimes more moderate chemicals) degrade resin so fibers can be liberated. The solvent needs to be recycled or disposed safely. Research is ongoing to reduce energy input, enhance fiber quality, and deal with adhesive / coating layers.

- Pyrolysis / Thermal: High‑temperature processes that break down resin into gas, oil, and leftover solids. Fibers recovered often degraded or with char residue. But upgrading thermal processes (control of atmosphere, temperature ramp, catalysis) is improving yields.

Design for circularity (forward looking)

Manufacturers in Europe are exploring designing blades from the outset for end‑of‑life disassembly. This includes using fewer different materials, modular joints, avoiding or simplifying adhesives, using cores that are easier to separate (or designing with foam cores that are more compatible with recycling).

Also, increasing use of thermoplastic resins, or bio‑resins, which can be re-softened or reformed, unlike most epoxies.

Market & policy incentives

In Europe, the call is for a Europe‑wide ban on landfilling decommissioned turbine blades by 2025. Some countries like Austria, Germany, Finland and Netherlands already have such bans.

Looking for a facility that handles composite blade waste responsibly?

We maintain a Europe-wide network of certified recyclers, co-processors, and solvolysis pilots.

Contact us:

Environmental, social, & economic costs and trade‑offs

Unfortunately, recycling is not “free”. There are always some kind of trade‑offs, and in some cases, poorly managed recycling or repurposing can cause harm. Any full solution must consider:

| Factor | What’s at stake | Key challenges / observations |

|---|---|---|

| Greenhouse gas emissions & energy input | Some wind turbine blade recycling methods use high heat, chemicals, or transport over long distances. If electricity grids or transport are high carbon, the “benefit” can be erased. | Studies show chemical recycling or high‑temperature thermal processes can have lower or comparable GHG emissions to landfilling + new material production, but only if operations are optimized. |

| Cost | The up‑front costs are high: cutting, transport, shredding, chemical handling. Often, recycled material enters low‑value uses. Without policy or subsidies, cost per kg of recycled fiber is much higher than virgin. | In many places landfill or incineration remains cheaper or easier under current regulations. Incentives, economies of scale, and material value must increase. |

| Regulations / Standards | Waste classification, legal status of composite materials, emissions from incineration, wastewater or by‑product disposal all influence what practices are allowed and cost. | Harmonization across jurisdictions is weak. Lack of clarity around “recycled fiber quality” standards or how recycled composites count in structural or safety applications. |

| Social implications | Local communities, environmental justice, aesthetics, land use. Landfills are often in less privileged areas. Repurposing or reuse offers community value. | Public acceptance of incineration or chemical plants can be low. Reusing blades in visible public applications (bridges, shelters etc.) can help social buy‑in. |

Policy, regulation & market dynamics

To tip the balance toward circularity, policy and market forces must align.

- Extended Producer Responsibility (EPR): If blade manufacturers are held responsible for end‑of‑life disposal or recycling costs, they have incentive to design for recyclability.

- Landfill bans / restrictions: Europe’s push to ban landfilling of blades (especially composite blade parts) by 2025 is a strategic lever.

- Standards & certification: For recycled fiber or composite materials to enter building, automotive, or new blade manufacture, standards must recognize and certify them.

- Incentives & subsidies: Grants, prizes for R&D; subsidies or tax credits for infrastructure; procurement requirements (e.g. procurement rules for wind farms requiring blades to be reusable/recyclable).

- Circular economy legislation: EU’s Circular Economy Action Plan, Waste Framework Directive, Green Deal, Renewable Energy Directive etc. These set legal and economic context.

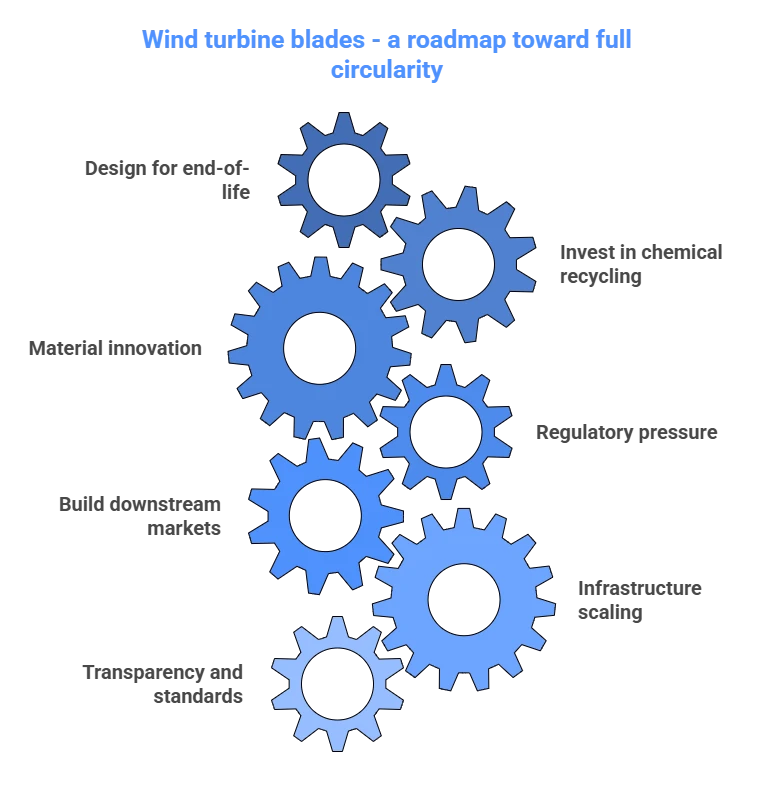

What must change: a roadmap toward full circularity

To “knock the knees” of inertia, the following must happen. These are levers that could shift blade disposal from being a looming problem to an industry success story.

- Design for end‑of‑life from the first cut

Use materials that allow separation; minimize adhesive complexity; select cores and coatings that are compatible with recycling or reuse; modular design. - Invest massively in chemical wind turbine blade recycling & advanced processes

Scale up solvolysis, pyrolysis, supercritical fluid processes; improve energy efficiency; ensure solvent recovery; reduce the damage to fibers, preserve resin when possible. - Material innovation: bio‑resins, thermoplastics, recyclable composites

If new blades can be built from materials that are high performing AND recyclable, the entire lifecycle improves. - Regulatory pressure & economic signal alignment

Landfill bans, EPR schemes, procurement rules, subsidies. Pricing disposal (or penalizing it) so that recycling becomes cost‑competitive. - Build downstream markets for recycled blade materials

Low‑value uses (aggregate in concrete etc.) help, but scaling high‑value uses (structural parts, automotive, new blade composites) is essential. That means quality control, certification, and demand. - Infrastructure & logistics scaling

Facilities for cutting, transporting large blade segments; chemical recycler plants; sorting and preparatory facilities. Too often these costs kill business models. - Transparency, standards, and measurement

Accurate data on blade material types, weights, volumes; global tracking of decommissioning; harmonized standards for recycled material strength, safety, and performance.

Quantitative benchmarks & targets

Here are key numbers that should become targets to measure progress. They help set ambition and allow accountability.

| Metric | Current / Baseline | Target by ~2030 | Target by ~2050 |

|---|---|---|---|

| Annual global blade waste | ~ hundreds of thousands of tonnes now; forecast to 2–3 million tons/year by 2050 | < 50% of blades sent to landfill/incineration; recycling / reuse / energy recovery for most portions | ~90‑100% circularity: highest possible reuse & recycling, minimal landfill/incineration |

| Recycled fiber retention (%) | Low; many mechanical processes reduce strength; chemical methods preserve more but are immature | Strength retention ≥50‑70% for glass fibers; for carbon fibers higher; cost at or near parity with virgin in some use cases | ≥80‑90% for fibers; resins increasingly recycled or biodegradable; reuse of whole blade structures commonplace |

| Cost per tonne of processed blade waste | High; variable depending on region | Reduced via scale, innovation, regulation to levels competitive with landfill + disposal fees + carbon costs | Low enough that recycling is default choice in most locations |

| Regulatory coverage | Patchy; some countries with landfill bans; many with no mandates | Broad EU harmonization; major wind‑markets (U.S., China, India) with regulations EPR / landfill bans etc. | Universal regulatory expectation; international best practices; supply chain requirements for recyclability |

| Materials innovation | Early pilot resins (bio‑resins, adaptables); some thermoplastic composites | Several commercial blade manufacturers using recyclable/bio resins; new blade designs standardized for disassembly | Majority of new blades built for circularity; repowering includes reuse of blade components at scale |

Why this matters: impacts beyond waste

Climate integrity at stake

Wind turbines are icons of clean energy, yet their sustainability must extend beyond electricity generation. When blades are dumped in landfills or incinerated, we undermine the net-zero ambitions they support. Recycling reduces emissions tied to virgin materials and cuts the embedded carbon in new blade production. It’s not just about waste—it’s about preserving the climate case for wind itself.

Materials & supply chain resilience

As wind deployment grows, so does the strain on materials like fiberglass, epoxy resins, and especially carbon fibers. These are energy-intensive to produce and often sourced from limited suppliers. Wind turbine blade recycling creates a parallel, localized supply stream, buffering the industry against shortages and geopolitical risk. It also future-proofs turbine manufacturing by easing dependency on virgin imports.

Economic opportunities in a circular market

Recycling isn’t a cost—it’s a value chain. From chemical separation to blade repurposing and fiber upgrading, this sector can support skilled jobs and new business models. Early movers—those who invest in scalable recycling, material refinement, and high-margin reuse—stand to gain market advantage. Circularity, in this context, becomes a competitive edge.

Public trust & social acceptance

Communities expect renewable energy to be holistically sustainable. News coverage of landfilled blades damages the credibility of wind power. Conversely, visible repurposing—turning blades into bridges or urban furniture—builds public confidence and reinforces wind’s social license. Recycling isn’t just operational—it’s a reputational imperative.

Policy momentum and future compliance

Regulators are tightening the screws. The EU is pushing landfill bans for blades, and extended producer responsibility (EPR) is gaining traction worldwide. Blade recyclability will soon be a requirement—not an option. Companies that prepare now will avoid regulatory shocks and unlock public procurement opportunities where recycled content is rewarded.

Avoid costly missteps in wind turbine blade disposal. We map your waste stream to the optimal processing plant—factoring in transport, material type, and regulation.

Contact us:

Before it’s too late

The clock is ticking. In just a few years, annual blade waste will reach enormous scales—tens or hundreds of thousands of tonnes in many countries, millions globally. We risk trading one environmental problem (fossil fuel emissions) for another (mass composite waste in landfills or incinerators) if we do not act.

Yet the tools exist: new resin technologies, chemical recycling, better design, strong policy levers. What is required is urgency, coordination, investment, and scope. If manufacturers, regulators, researchers, and civil society align, wind turbine blade recycling can become a flagship example of circular economy success.

In short: the next decade is make‑or‑break. Every blade recycled or repurposed is one less ton in landfill, one less virgin material sourced, and one more step toward sustainable wind energy that honors its mission—not just in generating power, but in how it treats its own shadows.