EPS recycling in Europe: how to get it right

EPS looks light, but the decisions around it are heavy. In Europe, a small slip on classification (naming the exact EPS type), paperwork, or densification (compressing foam to cut volume) costs time and money. This guide shows how to get recycling in Europe right and plan waste transport in Europe without any hiccups. When loads are clean, dense, and correctly coded, they move faster and earn more.

EPS recycling in Europe begins with the right classification

Why start with classification? Because it shapes everything else: the waste code on your paperwork, which facility can accept the load, how you prep the material, and your final processing price. A clear label and a short note on contaminants help hauliers plan, help plants quote, and help border officers check faster. While this may sound like the boring part, it’d allow you to save money later.

How to use this section?

First, match your stream to one of the types below. Then capture three basics on each pallet or big-bag: source, visible contaminants, and moisture/odor. Those small habits raise acceptance rates, especially for EPS transport in Europe.

EPS recycling in Europe by waste type — diversify your approach

There is no single “best” or “one-size-fits-all” method. You must diversify based on: the stream’s cleanliness, moisture, density, age and the destination’s capability. Then pick the route that protects value and stays compliant. Below, we go type-by-type, using the list from previous section.

Construction EPS (insulation)

- If HBCD is above waste limits, send to destruction and document the test.

- If non-HBCD (quick screen + lab if flagged), send to mechanical or dissolution recycling (dissolution = turning EPS back into polystyrene solution before re-making plastic).

Why it works: You avoid illegal shipments and rejected loads. You also protect recyclers’ specs.

Packaging EPS

- Keep it dry and odor-free; note “no organics” on the label.

- Densify at source (compress by using cold press or hot-melt to reduce size) to cut freight per tonne.

Why it works: Recyclers pay more for clean, dense, mono-material loads; carriers load faster; borders check quicker

EPS beads

- Bag with liners; seal spouts; keep spill kits on hand.

- Reuse internally where possible; log re-feed ratios.

Why it works: You keep material in spec and off the floor (spills create compliance and safety issues).

Geofoam

- If not reusable, size-reduce and send to recycling.

- Recut blocks to standard sizes first (some buyers want blocks, not regrind).

Why it works: Cutting trims transport cost and matches buyers by geometry, not just polymer.

Specialty/functional EPS

- Secure route to buyers able to handle that spec or to approved destruction if required.

- Confirm the additive; segregate storage.

Why it works: You avoid cross-contamination and rejections.

Civil-engineering EPS

What to do:

- If yield fails the economics, send to energy recovery and record why.

- Trial-clean a small batch; check yield (yield = % that becomes saleable recyclate).

Why it works: You save time and cash by testing before full loads.

Disposable EPS

- Where legal, recycle if clean; where restricted, plan recovery.

Why it works: You align practice with law and keep messaging clear for collectors.

Country practices by stream

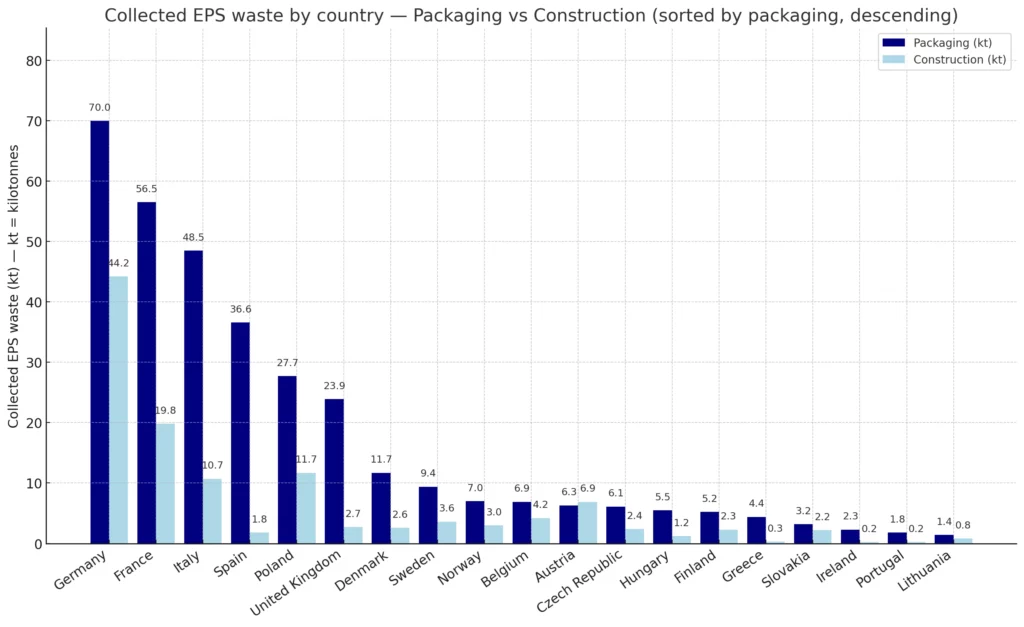

Based on the “The EPS-industry’s journey towards circularity. Progress report” publication, about 507,000 tonnes of post-consumer EPS packaging and construction waste were collected in Europe in 2019. Roughly 30% was recycled, 46% went to energy recovery, and 24% to landfill. Packaging made up ~73% of collected EPS waste. Several countries exceeded 45–50% packaging EPS recycling in Europe, including Portugal, Norway, Denmark, Netherlands, UK, Austria, Belgium, and Ireland (based on industry and national association data).

Germany (~114 kilotonnes) led EPS waste generation, followed by France (~76 kt), Italy (~59 kt), and Poland (~39 kt) in 2019.

EU-wide, about 41% of plastic packaging was recycled in 2022; leaders included Slovakia (60%), Belgium (54%), Germany/Slovenia (51%). This frames what “good” can look like for plastics logistics programs.

Nordics report very high fish-box capture; Norway cites ~90% recycling for EPS fish boxes with efficient harbor collection and export to EU recyclers.

Every country faces different recycling challenges. If you’d like tailored advice on how to optimize your EPS recovery in your region, reach out to us:

Source: The EPS-industry’s journey towards circularity. Progress report, which was already mentioned in this section.

As shown in the chart above, Germany, France, and Italy dominate EPS collections from packaging, together contributing over half of the total. Overall, packaging volumes are nearly three times higher than construction EPS, revealing a persistent gap in capturing material from building sites. Notable outliers include Austria—where construction exceeds packaging—and Spain and the UK, which collect substantial packaging but very little construction EPS. Poland shows a stronger balance, ranking behind Germany and France in construction volumes. Priority actions: enforce on-site segregation, deploy mobile densifiers at large projects, and formalize take-back routes during renovation and demolition.

The laws that matter — and why you should also keep them in mind

Single-use plastics (SUP) rules: Since 3 July 2021, the EU has banned placing EPS food and drink containers and cups on the market. Why it matters? Because these items will show up less in future collections. When present, they require clean handling and clear messaging to avoid contamination.

Basel/WSR plastic shipment rules: Clean, sortable plastic waste that is destined for EPS recycling in Europe can fall under B3011 (the “green-list” entry). But mixed/hard-to-recycle plastics fall under Y48 and are banned from export to non-OECD, while hazardous plastics fall under Basel code A3210. Why it matters? Because your waste code must match the actual spec on the truck. A wrong code leads to stops, returns, or penalties.

POPs/HBCD limits in waste: Old EPS insulation can contain HBCD (flame retardant). If waste exceeds the EU low-POPs (persistent organic pollutant) limit of 1,000 mg/kg, recycling is not allowed and the load must be disposed of (via thermal means or equivalent). Why it matters? Because a quick screen avoids illegal shipments and protects your buyer. Note: separate, lower limits apply to new products/mixtures (e.g., 75–100 mg/kg as unintentional trace contaminant), but the waste cut-off for HBCD remains the key shipping trigger.

EPS transport in Europe explained

How to handle styrofoam waste transport? Here are four useful tips:

Need help putting these steps into practice? Our team can guide you through every stage of EPS transport — from paperwork to carrier selection — so your shipments move smoothly across Europe. Contact us:

The economics — three variables that move your netback

Profit in EPS recycling in Europe comes from three levers that work together: what you pay to move a tonne, how much of that tonne turns into saleable material, and where your quality lands on a buyer’s price scale. Think of netback as your “money left after all costs” (sale price minus freight, handling, and fees). Lowering transport cost changes the math first. When you densify foam, you ship less air and more plastic, so the €/t delivered falls. Even moderate compaction shifts you into fewer trucks, which frees budget for better prep and testing.

That same prep lifts yield (the share that becomes regrind or pellet). Clean, dry packaging streams lose less to washing, de-dusting, or disposal; therefore, recyclers pay more and pay faster. Construction streams behave differently, because legacy flame retardants or adhesives can drag yield down; quick screening and honest labels protect both sides and avoid claims that erase margin.

Quality drives the final step. Most buyers pay within price bands (quality-based ranges) set by simple checks: density, moisture, ash, whiteness, and odor. When your loads hit the target density, arrive dry, and pass a sniff test, you climb a band without haggling. As a result, the same tonne earns a better price with no extra miles. Put plainly: densify to cut freight, clean to raise yield, and document quality so buyers can pay the higher band. Do those three together and your netback rises, which is exactly how EPS transport in Europe turns from a cost center into a controllable profit lever.

Risks you can actually control — and how to do it

Risk in this space looks complicated, but you can manage it with a few steady habits. The first is regulatory fit. Shipments move smoothly when the code on the document matches the material on the truck. Border staff do not expect poetry; they expect proof. A short code memo (one page that explains why you chose that code) plus a quick screen for HBCD in insulation keeps you on the right side of EU rules. When a sample flags red, you route to the right outlet and record the decision. That small act prevents stops, fines, and returns that burn time and reputation.

The second risk is operational. Wet fish boxes, bead spills, and stale-odor storage turn good material into a problem. Covered areas, lined big-bags, sealed spouts, and simple photo notes at dispatch fix most of it. People respect what they can see, so photos of each lot—angles, labels, and a size reference—settle arguments before they start. Finally, there is contract risk. Vague specs invite disputes; clear tolerances (for moisture, density, and contamination) invite trust. When a load misses, a written retest path and a calm rejection protocol keep relationships intact. None of this requires heavy jargon or big budgets. It requires rhythm: the same tests, the same labels, the same photos, every time. Keep that rhythm and your compliance improves, your claims fall, and your cash cycle speeds up.

The right support makes a big difference

Here at Waste Transport Solutions, we aim to make EPS recycling and transport simple, compliant, and on time—so your team can focus on operations, not red tape. We start with documentation so your shipment meets every requirement under European law. That means we check the documents for the right waste code, compile lab results when needed, and prepare a clear “code rationale” note (a short memo that explains why a code fits the actual material). We also stack the pack in the order inspectors expect—contract, origin, tests, and routing—so checks are quick and consistent. As a result, EPS transport in Europe moves with fewer stops and fewer questions.

Next, we coordinate the carriers. We only book competent hauliers with up-to-date transport permits. Before any truck rolls, we verify coverage, validity dates, and route scope. This avoids roadside delays and prevents last-minute detours. Consequently, your waste reaches the processing plant on time, which supports stable pricing and cash flow.

Finally, we protect the environmental outcome. We audit the destination in advance and match your stream to the right outlet—recycler for clean packaging EPS, or the appropriate alternative when insulation contains legacy HBCD (flame retardant). Our due-diligence check includes a paperwork review and, when appropriate, a site inspection of the processing plant (the facility that recycles or recovers energy). Because we prioritise proven outlets, EPS recycling in Europe becomes both compliant and credible—good for audits, and better for your brand. So if you need help managing your styrofoam waste, look no further and send us a message at office@wastetransportsolutions.eu.