Cardboard vs. paper: the recycling mistakes you didn’t know you’re making

Cardboard recycling may seem like a no-brainer—flatten, toss, repeat—but that familiar box has a secret. It doesn’t belong in the same pile as your office paper or yesterday’s newspaper. While both materials start from similar pulp, their afterlives depend heavily on how they’re sorted, handled, and treated. And if you think one-size-fits-all recycling is harmless, you’re in for a surprise.

Cardboard recycling sounds simple. Yet once you mix it with office paper, quality drops and compliance risk rises. Both materials begin as wood pulp, but they behave differently during collection and transport.

At a glance, they look like twins. In reality, they’re cousins with different needs. Therefore, one “anything fibrous” bin quietly sabotages yield, drives up rejections, and drains value. This guide explains the similarities and differences so you can sort smart, train teams with confidence, and keep costs predictable.

So similar yet so different – paper vs cardboard recycling

Here’s the side-by-side view. It highlights what the streams share, where they split, and how that changes day-to-day handling.

ASPECT | PAPER (office sheets, mail, magazines) | CARDBOARD (corrugated/OCC, boxboard) |

|---|---|---|

Composition | Cellulose fibers with fillers and coatings; high print/toner exposure; may include windows/laminates. Fibers shorten each loop, so mills blend in fresh pulp. | Cellulose fibers too, but typically longer, tougher (liners/fluting). Fewer fine coatings; often carries tapes and labels. |

Origin | Information carriers: books, documents, forms, notebooks, flyers, posters, newspapers, magazines, catalogues, direct mail. | Shipping boxes, outer packaging, e-commerce cartons, shelf-ready trays, appliance/furniture cartons. |

Preparation if clean | Keep dry; remove spirals/clips; separate clean office grades; avoid mixing glossy/laminated items unless accepted; bale to standard office grades when feasible. | Flatten and nest; remove big films/straps; trim heavy tape when practical; store under cover; bale to ordinary corrugated grades. |

Preparation if contaminated | Keep liquids out; route laminated/glittered or heavily inked items per collector rules; bag shredded only if accepted; exclude food-soiled paper. | Tear off heavily greasy panels (e.g., pizza bases); keep only clean board; remove food residues; moisture control is critical. Light surface grease on clean lids is often acceptable. |

Recycling | Sensitive to inks/laminates; clean grades de-ink well; fiber length drops each loop, so furnish gets blended. | Robust pulping for OCC; markets are deep; contamination is mostly mechanical (tapes/labels) rather than chemical. |

Reuse potential | Limited (scratch pads, internal reuse). Main value through clean recycling. | Strong: box-reuse for shipping/storage before baling; then high-yield recycling preserves value. |

So, which is easier to handle? Cardboard usually wins. Its contaminants are visible and simple to cut out, it baledensely, and market pull is steady.

Which is more promising for reuse/recycling? Cardboard again has the edge thanks to reuse potential and resilient OCC (old corrugated container) demand. However, clean office paper still runs smoothly and sells well when grades stay pure. When in doubt, optimize the cardboard lane first—then tighten the office-paper lane for steady gains.

Born different: why paper and cardboard recycling don’t share the same rules

Usage shapes regulation. Paper exists to carry information—think books, newspapers, exam papers, forms, posters, catalogues, notepads, and leaflets. Cardboard exists to protect goods through supply chains—outer boxes, sleeves, retail-ready trays, and shipping cartons. Because purpose differs, law splits the rulebooks.

Waste Framework Directive

At the top sits the Waste Framework Directive (WFD), which sets the waste hierarchy and core duties for anyone who produces or handles waste. It applies to both streams and defines when something is waste, how recovery is prioritized, and what “end of waste” can look like. This umbrella keeps basic obligations aligned across materials

Packaging and Packaging Waste Regulation (PPWR)

Packaging, however, has its own playbook. The Packaging and Packaging Waste Regulation (PPWR) entered into force in February 2025 and starts applying broadly in August 2026. It replaces the old directive model with directly applicable rules on design-for-recyclability, on-pack sorting labels, recycled content, and producer responsibility. Because cardboard is mostly packaging, it now carries tighter, harmonized obligations than non-packaging paper (books, office documents, posters, etc.). In practice, you must keep packaging grades separate, label them correctly, and report them consistently—or face avoidable friction and fines.

Member States hard-wire these ideas locally. Germany’s VerpackG ties packaging placed on the market to LUCID registration and licensing, making producers finance collection and recycling; that’s crucial for cardboard flows. France mandates Triman + Info-Tri sorting instructions on packaging to cut contamination at the source. Poland’s BDO register strengthens traceability for both streams through digital records. The common thread is simple: packaging (cardboard) draws stricter, clearer obligations than non-packaging paper because its use case floods systems with short-lived, logistics-heavy items.

Waste Shipment Regulation

Cross-border movements add a final layer. The current Waste Shipment Regulation—Regulation (EC) No 1013/2006 — governs how paper and cardboard travel between countries. A new WSR (Regulation (EU) 2024/1157) is adopted, but most provisions apply from May 2026. Until then, 1013/2006 stays operational. For clean, well-sorted fiber, the law allows “green-listed” moves with lighter controls. For contaminated or misdeclared loads, it requires notification and consent. Purpose before waste drives this split: packaging goes through a tougher compliance funnel, while non-packaging paper mainly follows general waste rules.

Hidden behind digits – different waste codes and their explanation

Codes decide whether a truck rolls or waits. Paper and cardboard look straightforward; the paperwork doesn’t. This section turns those digits into clear, usable guidance. First, think in two layers. The EWC (European List of Waste) identifies what the material is and where it came from for domestic records. Then, the Basel/WSR layer (Basel Convention and the EU Waste Shipment Regulation) governs how that same material moves across borders and which documents you need.

However, quality changes the lane. Clean, well-defined paper and cardboard usually qualify as green-listed for recovery (lighter controls). Add moisture, food, or messy mixes and the load can switch to amber—which means prior consent and tighter checks. Inspectors read the bale, not just the label, so accuracy matters.

Therefore, let’s make it practical. Below you’ll find all the relevant paper and cardboard codes under both systems, line by line. You’ll see why the same waste shows up under different codes, what that implies for transport, and why “code-swapping” at roadside checks risks fines—and reputation. If in doubt about a cargo or its producer, walk away. Losing one order is cheaper than losing your margin, permit, or reputation.

European List of Waste

PRO TIP

Use 15 01 01 for packaging, 20 01 01 for non-packaging paper/cardboard, and 15 01 06 only when it’s truly mixed and cannot be split.

Basel Convention + EU Waste Shipment Regulation (WSR 1013/2006)

Basel Annex IX (List B) – “green-listed” paper entries

WSR 1013/2006 mapping and EU-specific entries

Why the same material has different codes (and why you should care)

CODE-SWAPPING: THE SHORTCUT THAT CAN COST YOU BIG

Some companies try to label a mixed or food-stained OCC bale as B3020 to “sail through”. Inspectors look at grade, moisture, visible outthrows, and odour; they also know Annex IIIA mixture rules and are aware what B3020 covers. If the load doesn’t fit, they reclassify, fine, and order take-back. Misdeclaration = illegal shipment. So, stay on top of your codes and quality. If you doubt the waste or its producer, walk away. It’s better to lose one load than lose money, permits, or reputation.

Need help staying compliant across borders?

Waste Transport Solutions ensures your shipments pass inspections—no surprises, no delays.

Know the risks, avoid the surprises in cardboard recycling

Misclassification is risky, but consequences vary by role. Understanding them helps you design controls that actually work. Here are the most common risks that every party involved in paper and cardboard waste management can face.

Waste producers (shops, warehouses, offices)

Carriers/brokers

Recyclers/MRFs/mills

Everyone

From pitfalls to playbook: your step-by-step guide

Here’s a short guide on how to prepare your waste for recycling:

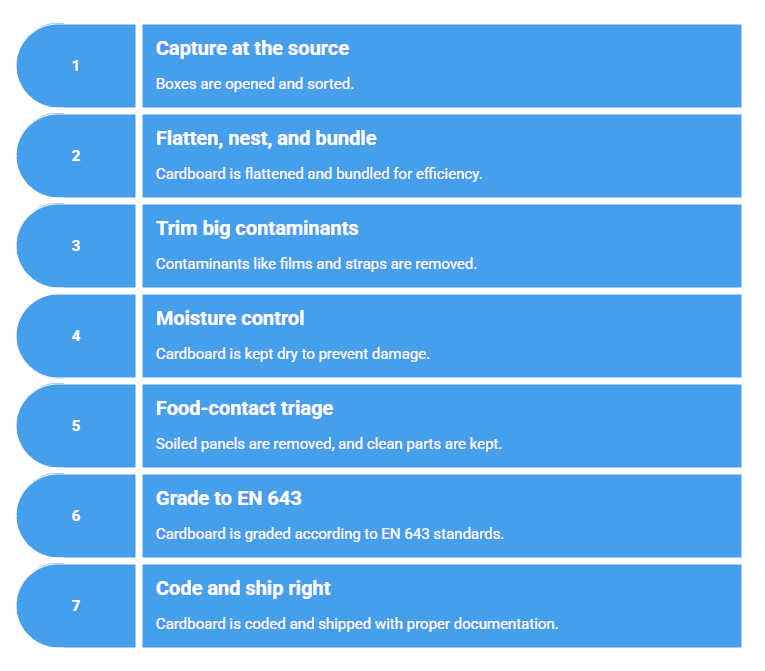

Cardboard recycling – 7 steps to get it right

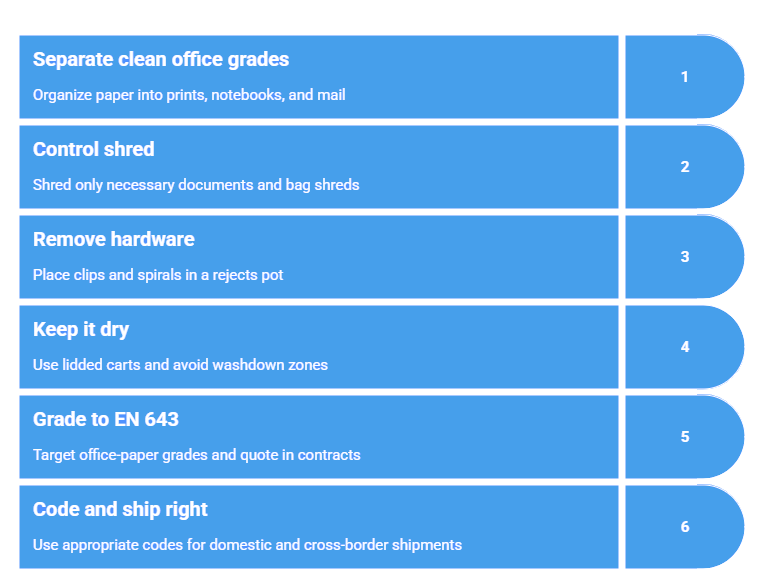

Paper recycling – the smart sorting checklist

Ready to simplify your recycling?

From documents to shipment, our team takes the complexity off your desk.

Let’s work together:

Recycling is no gamble—unless you play it wrong

If a mistake can stall a truck, void a contract, or trigger a fine, then it’s not “just recycling”. Paper and cardboard are different beasts, and they must be handled with precision—at the bin, on the bale, and across borders.

At Waste Transport Solutions, we make sure every step is covered: from waste production to carrier selection, from flawless documentation to final processing at the right facility. Choose stability over uncertainty. Choose us. Contact us at office@wastetransportsolutions.eu.